63 - How does the dosing order affect the dosing results with a gain-in-weight dosing system?

First a quick reminder: with gain-in-weight dosing systems the components are dosed separately, one after the other – in batches or asynchronously – into the weigh bin where the weight increase in the bin is measured. Usually, the main component is dosed first and then the secondary component(s).

However, it may be better to dose the secondary component first if it has varying bulk densities or is non-free-flowing. The main component would then be adjusted to the actual mass. In this case it is important to bear the size of the weigh bin in mind, so that there is enough space for the main component even if the secondary component has been over dosed.

If very small amounts are being dosed then it may be possible that the absolute dosing deviation can be quite high in relation to the target amount. If a dosing device has deviation of +/- 2 grams while the target amount of the dosed material is just 6 grams, the deviation is 33%. If the main component is dosed first, then it is very difficult to compensate for the incorrect dosing of the small amount of secondary component.

Therefore, for cases like this, the secondary component should also be dosed first, because the controls can react to deviations better when dosing the main component. In these cases, it is also important to bear the size of the weigh bin in mind. Additionally, the percental dosing deviation is reduced for larger dosing amounts.

Because regrind is already “pre-“mixed and contains all components, the added part has no effect for the percental composition of the components. All that needs to be adjusted is the amount of virgin material, depending on the amount of regrind. For example, if 50% regrind is being processed, only 50% virgin material will fit in the weigh bin. However, if the mill runs out, there won’t be enough regrind available. If virgin material was dosed first, there won’t be enough regrind, which can result in throughput problems. This is why it is also better to dose regrind first and then the virgin material.

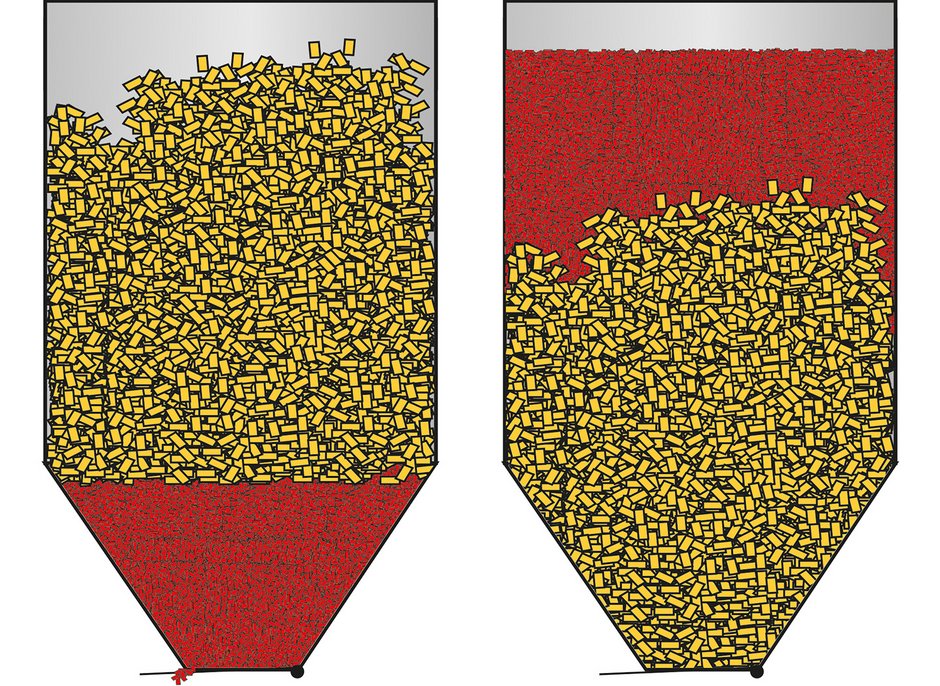

Very fine, free-flowing components that may have a tendency to flow through (technically) closed outlet flaps are a special case. Here is may be helpful to first dose a part of the usually “coarser” component(s) to seal it off and only then the “problem” component.

Do you know our gain-in-weight dosing systems already? For more information please visit www.motan.com