56 - Stable production with automatic dew point regulation

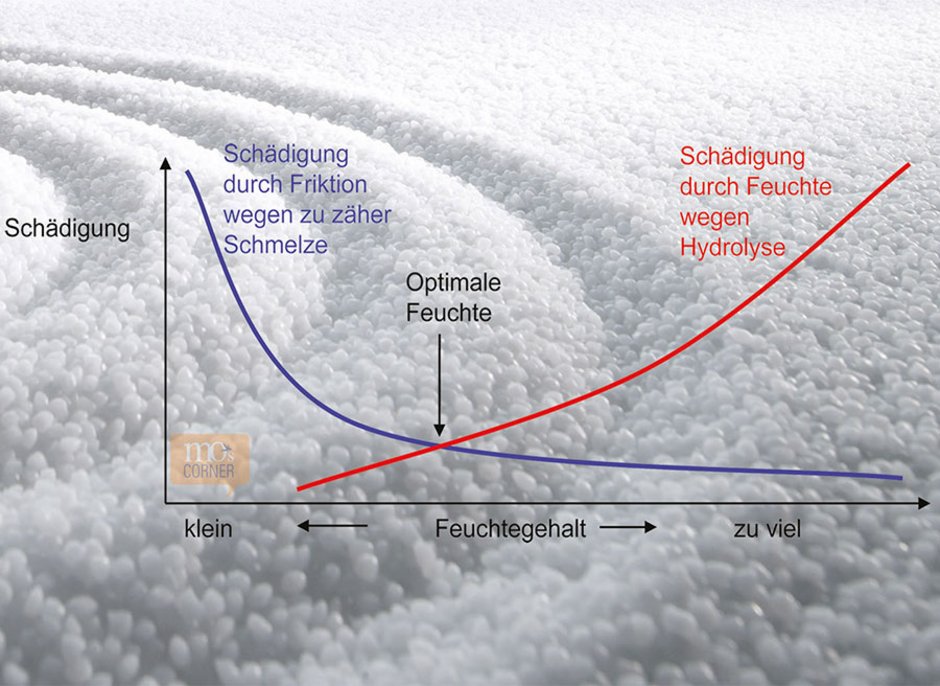

When processing plastic, the moisture content of the material is a deciding factor for production safety and product quality. Even more important is a defined residual or processing moisture content of the granulate, as this contributes to stable and precisely reproduceable production conditions. The raw material producers calculate and supply these material specific values.

Especially for materials that must not be under or over dried and need to be processed in a very small processing window, automatic temperature and dew point levelling can be beneficial. A drying system with a regulated dew point can keep the residual moisture of the material nearly consistent.

Just a quick reminder of the 4 important interdependent parameters for drying plastic:

- Drying temperature

- Air flow

- Dew point temperature

- Drying time

These parameters need to be coordinated with each other, as all of them influence the drying process and the results. In praxis, the goal is then to ensure a defined and reproduceable residual moisture that is independent of throughput. For this it is necessary to find a suitable combination of air flow, drying time, dew point and drying temperature. In principle, this balance is possible with various different parameter combinations.

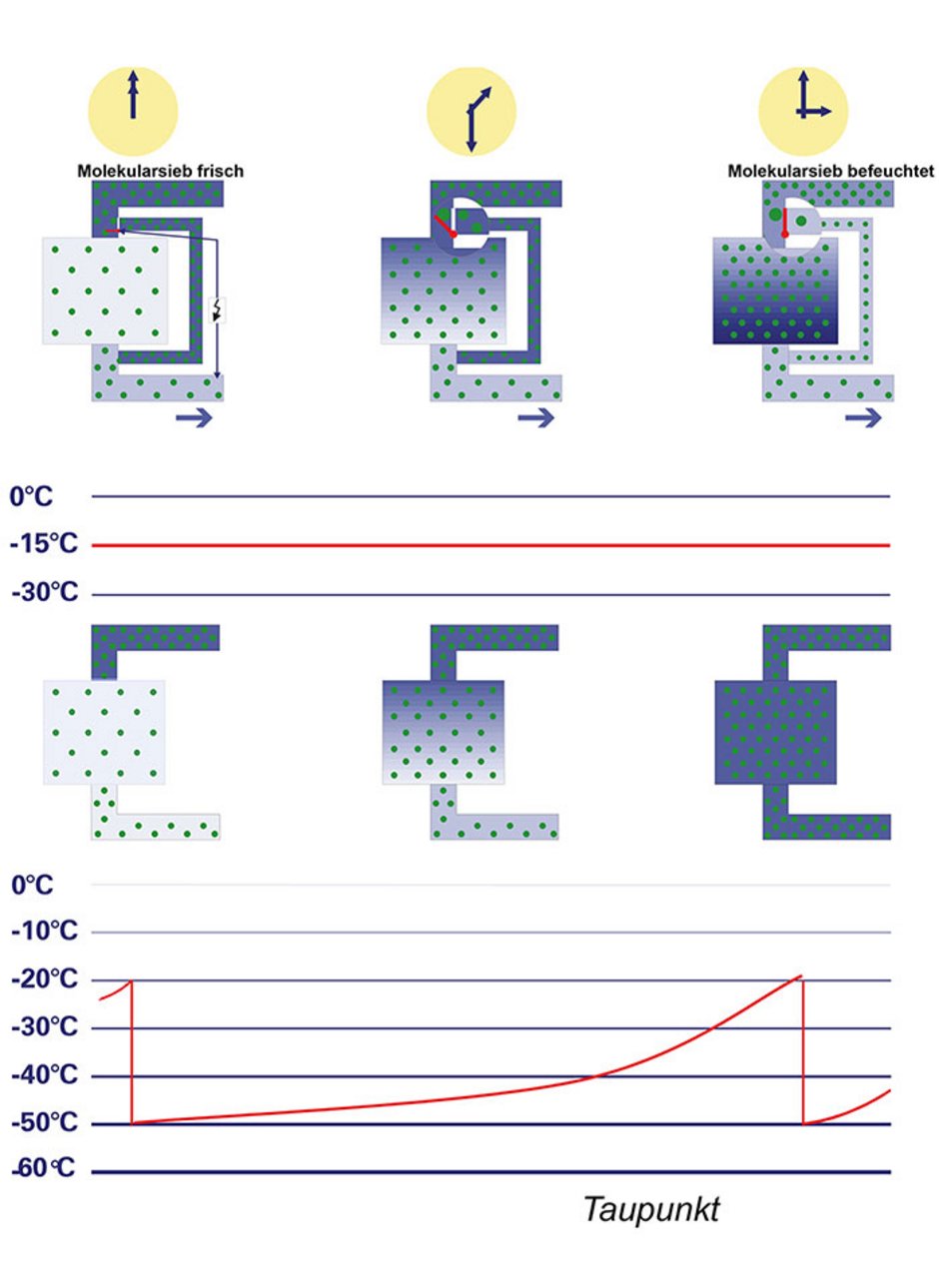

The whole thing becomes problematic when the allowed residual moisture of a material is within a very small range. With conventional drying systems the desiccant bed cartridges are regenerated after a certain amount of time or at a previously set, highest allowed dew point temperature. In the best case then, it is only ensured that the dew point doesn’t go above the highest allowed value (e.g. -20 °C). The lowest dew point is not monitored. Freshly regenerated desiccant beds can supply dew point temperatures of -50 °C and lower. The dew point temperature only rises once saturation starts increasing.

If the dew point temperature is too low initially and does not remain constantly at the required level, delicate materials can be damaged.

This is where automatic temperature and dew point levelling comes into play. It was specifically designed for applications where material cannot be either under or over dried. The dew point of the process air is regulated to maintain a set value.

This is possible, for example, by adding process return air to the dry air via a regulation valve before the desiccant bed. As much “humid” return air is added until the set dew point temperature has been reached. The available process air has a consistent dew point, that can be regulated with accuracy of ± 1 °C and can be documented.

You want to see how the drying process can work within a system? Find out more on www.motan.com