02 - What is the difference between volumetric and gravimetric dosing?

Put simply, dosing systems dispense predefined amounts of material in a specified time period in a defined ratio. The recipe is based on the mass, not the volume, of the chosen ingredients. Dosing can be influenced by the type and properties of the input material, ambient conditions (temperature, humidity, etc.) and the type of dosing device (see our first column). But there is another important factor to consider: whether you use a volumetric or gravimetric system.

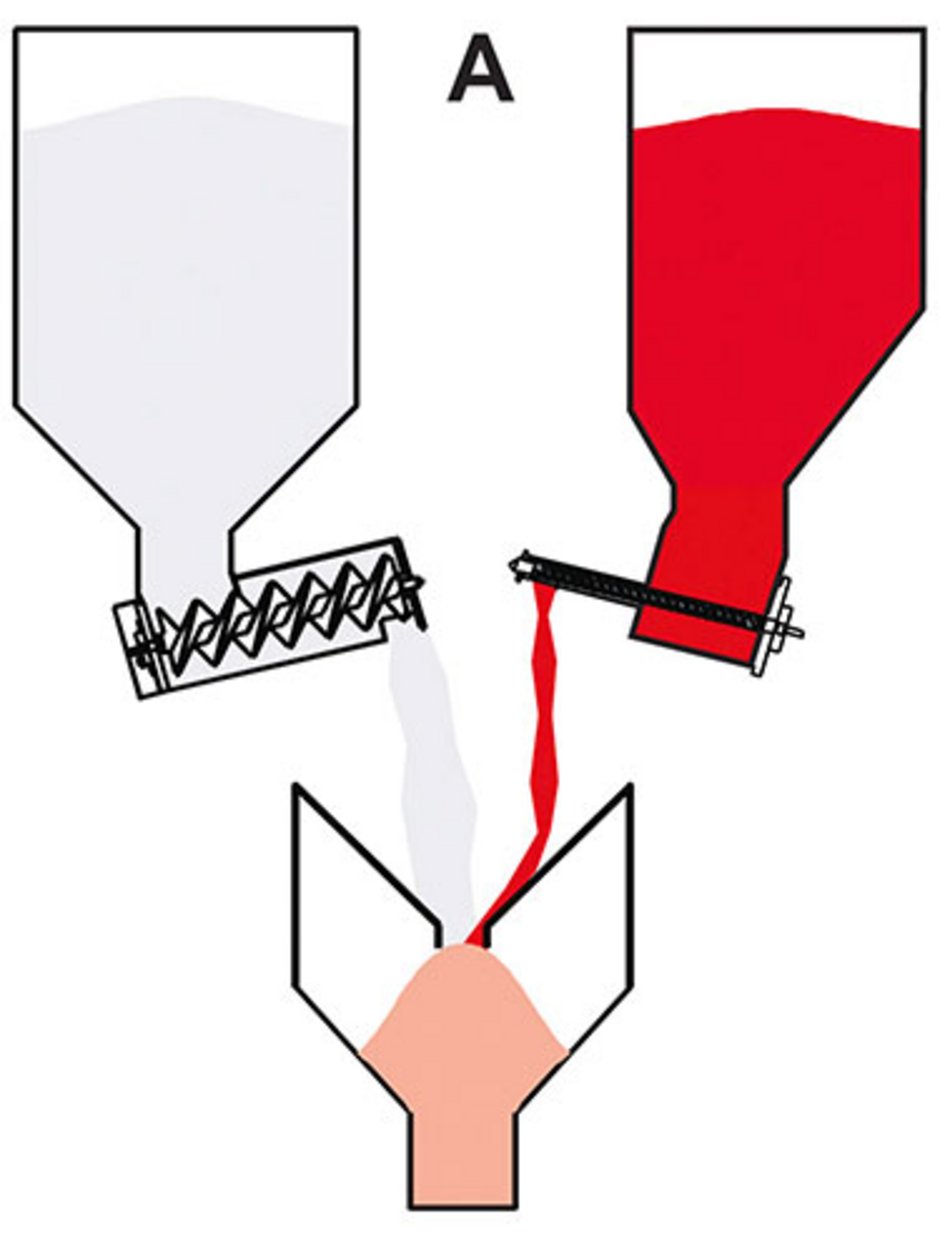

As the name suggests, volumetric dosing systems only measure the volume of the ingredients (in cubic centimetres or meters, for example). Because the dosing device does not weigh the components, it must be calibrated to ensure that the correct mass is dosed over a set period. This means it must be recalibrated every time a new material or batch is introduced. Volumetric systems cannot automatically make adjustments for fluctuations in properties such as input material bulk density – and to play it safe, manufacturers tend to deliberately set the system to dispense a larger amount than is actually necessary. It is also important to ensure that the same amount of material is placed in all the “volumetric chambers” within the dosing device, be it a screw, disc or chamber.

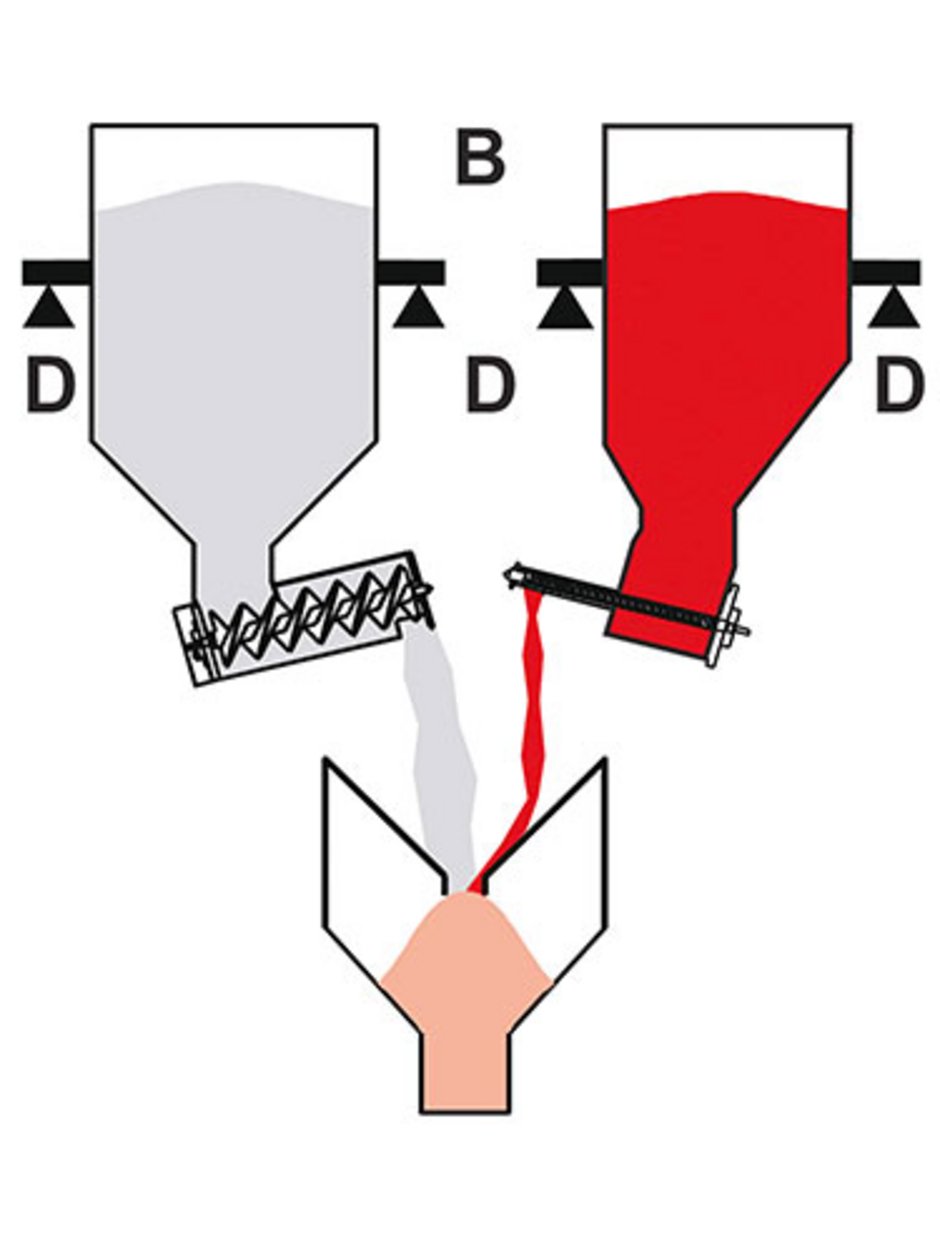

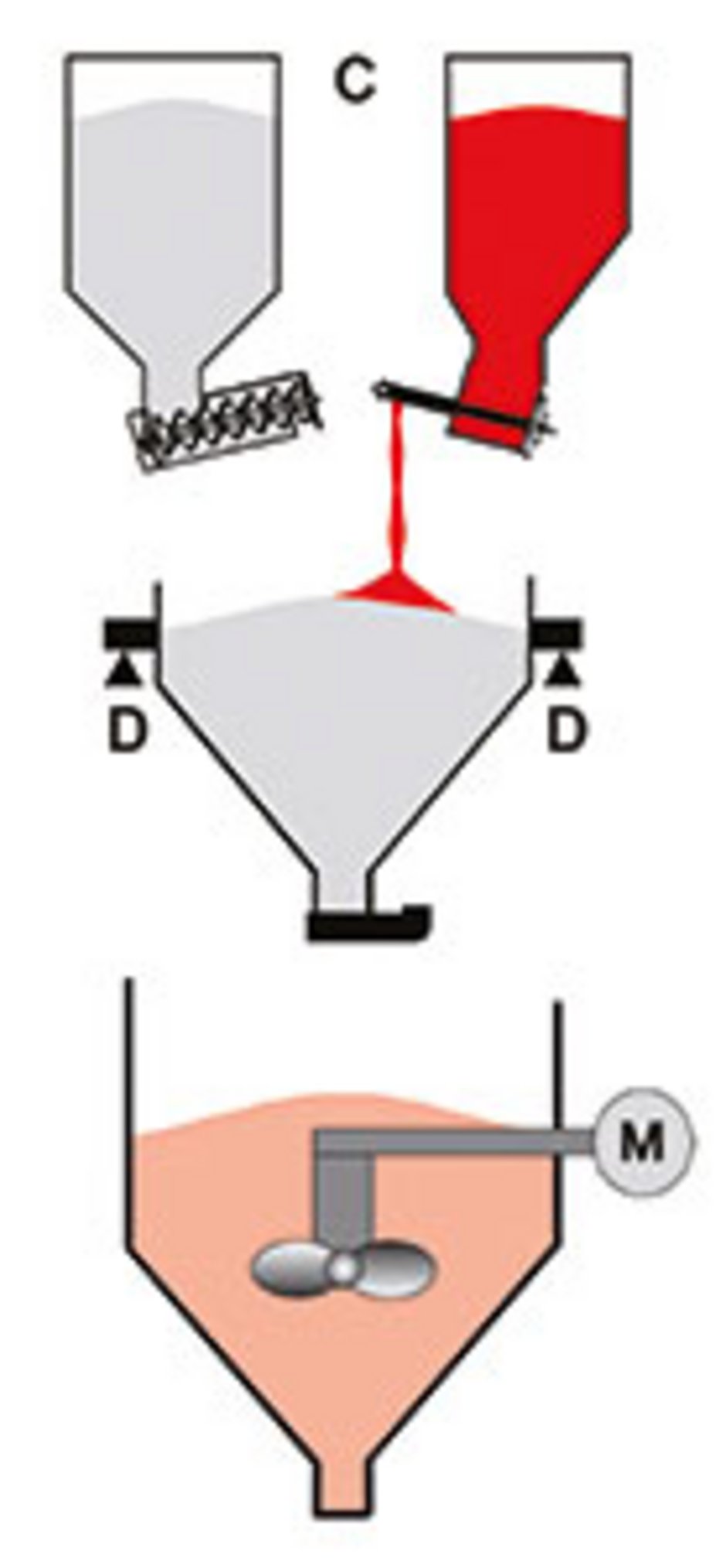

Gravimetric dosing systems, on the other hand, use one or more integrated weigh cells to measure input material. This means that mass is the only parameter considered. Because the system continues to dose material until it reaches the required target weight, fluctuations in density do not affect the outcome. A further benefit is that you can say with certainty how much total material – by weight – has been used, this is very important if you need to document the process for quality management purposes.

An example from around the home clearly illustrates the difference between volumetric and gravimetric measurements: 250 ml of liquid cream will become around 1000 ml when whipped – but its mass will remain constant at 250 grams.

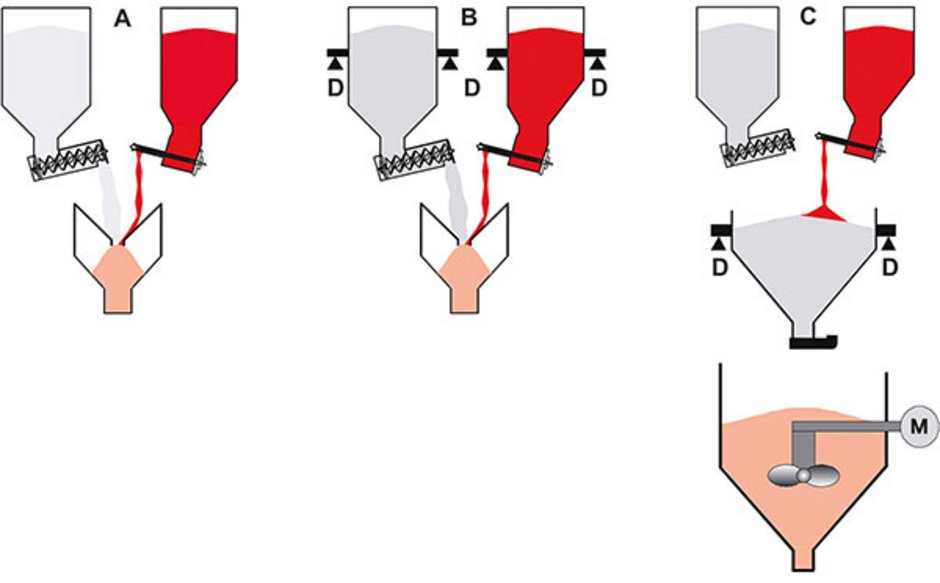

Whether you use a gravimetric or a volumetric system, you can choose between synchronous or asynchronous operation – in other words, the components can be simultaneously dosed together straight into the process, or they can be first dosed and then mixed together in a second, separate step. If you are deploying an asynchronous system, a mixer must be installed downstream of dosing to mix the ingredients after they have been metered into the reservoir.

In the next instalment, we will take a closer look at volumetric and gravimetric dosing systems in terms of design and how they work.

You want to see different models of gravimetric and volumetric dosing systems? For more information please visit www.motan.com