K Show 2022 – motan presents a new dryer series and products of the new product brand “swift”

LUXOR SG – Compact and mobile dry air dryers with state-of-the-art control technology

The dry air dryers of the LUXOR SG series represent the latest generation of compact and mobile dry air dryers. They are characterized by the combination of the well-known reliable process technology and state-of-the-art control technology, thus ensuring a perfect drying result. With the ecoPROTECT function installed as standard, the dryers offer an energy-saving drying process which guarantees that the material is not over- or under-dried.

"swift" - New cost-effective products in proven motan quality

In addition, motan will be launching for the first time to the European market at the K show some products from the "swift” brand. These products have been specially designed as cost-effective entry-level models. These standardized products have an excellent price-performance ratio and feature the latest control technology.

sCOMPACT - Energy-efficient 4-in-1 drying technology

The sCOMPACT dryers with integrated conveying are multifunctional and flexible. The dryers are available in three versions and are each equipped with one drying bin of the size 80, 150 or 250 litres and up to three sCONVEY hopper loaders for conveying to the drying bin and two processing machines. In addition, the sCOMPACT has a unique feature and can control an sCOLOR V additive dosing unit. The dryer is also offered with advanced features such as dew point control and dry air conveying function with line purging. Operation is through the integrated 7’’ full colour touch display. The complete drying bin is fully insulated, made of stainless steel and has a large access door. The integrated conveying system in the sCOMPACT saves space and money, as no additional equipment is required.

sCONVAC - Compact solution for simple central conveying

The flexible sCONVAC conveying station enables cost-efficient operation of small conveying systems. With a wide range of blower sizes, the conveying station can be used for a wide variety of central conveying applications. The three-phase blower is low-noise and maintenance-free and is protected by a cyclone filter with dust collection container. With the integrated sCONVAC control, the conveying station can control up to eight sCONVEY HOS material loaders and eight line purging valves. Everything is controlled via a 7” full colour touch display.

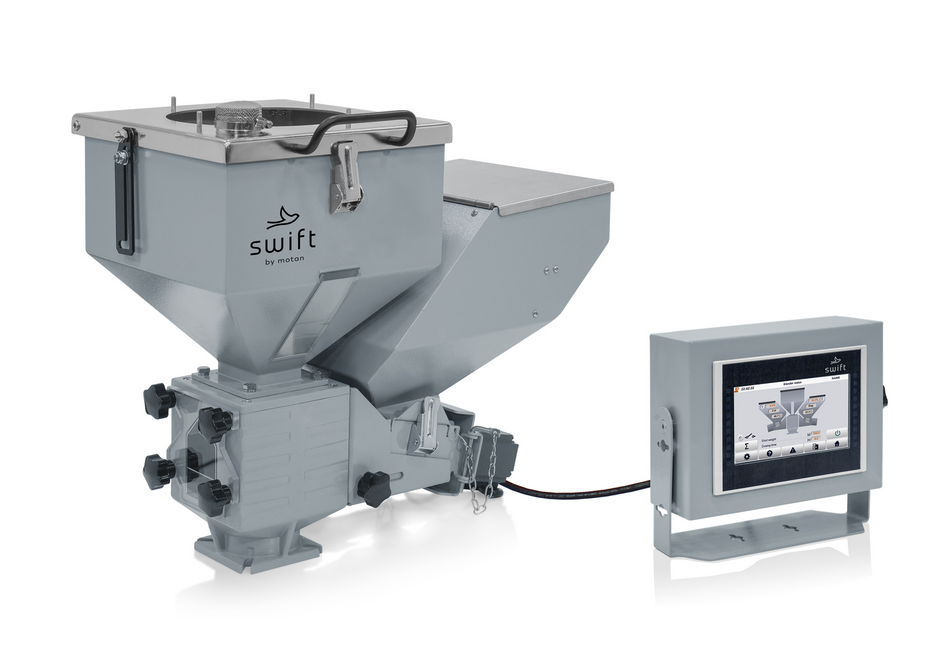

sCOLOR V - Consistent and accurate masterbatch dosing

The volumetric additive dosing unit sCOLOR V offers excellent mixing quality and reliable, accurate and consistent dosing of additives. The unit is compact and designed to be directly mounted on the feed throat of the processing machine. Excellent recipe accuracy is achieved through synchronous dosing. This results in greater transparency and traceability for quality assurance of the end products. As with all swift products, the unit is controlled via a 7” full colour touch display.