Bespoke Compressed Air Dryers for Clean Room Production

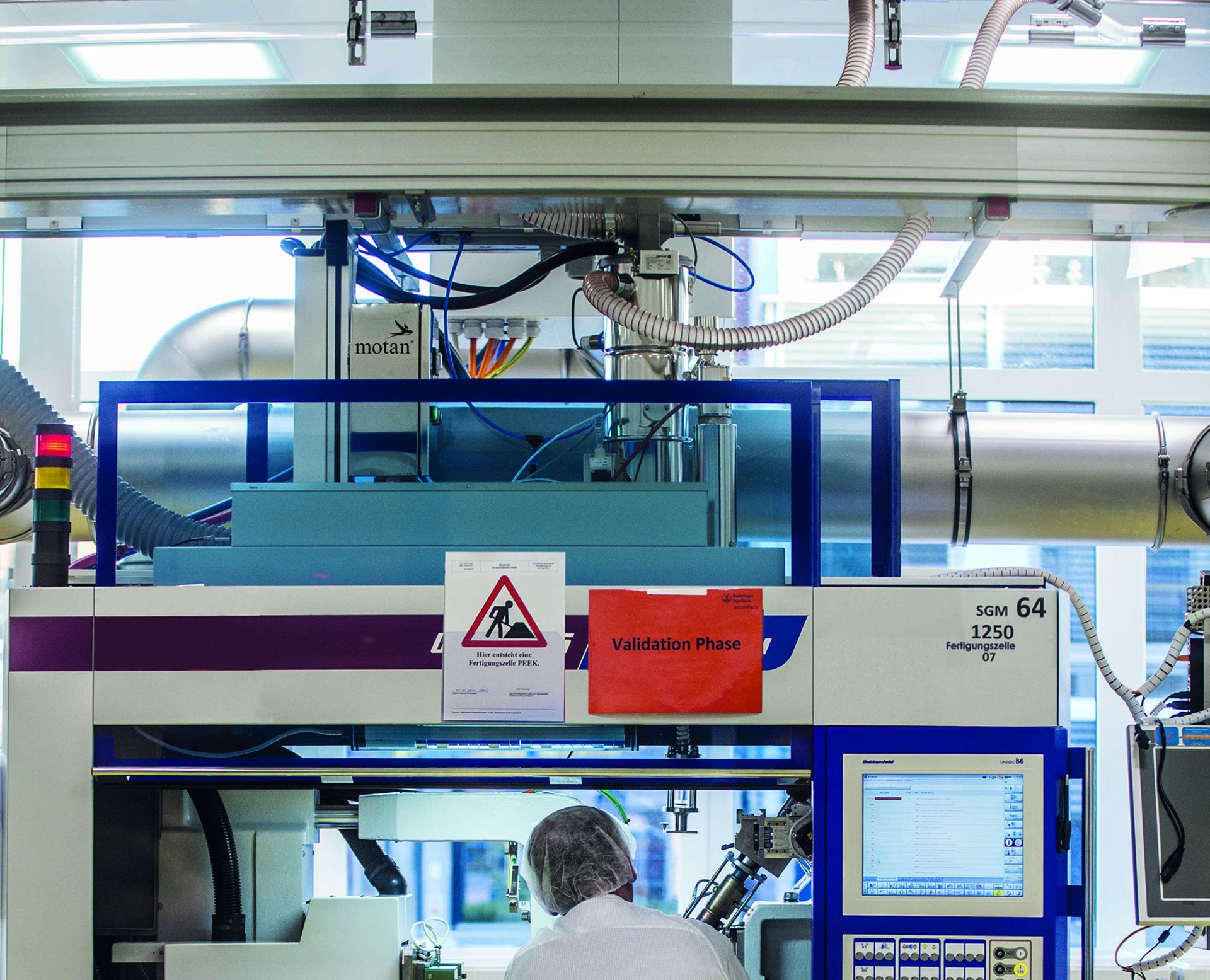

The Dortmund-based German company Boehringer Ingelheim microParts GmbH has set up a new clean room manufacturing area for the production of small and extremely small PEEK moulded parts as part of a recent product expansion project. Because of the parts' low throughputs, installing a central compressed air drying system was out of the question. Hence, Motan-Colortronic developed and supplied a bespoke material conveying system with twelve specially-designed compressed air dryers that are integrated into a centralized conveyor control unit with a centralized process visualization system.

Boehringer Ingelheim microParts produces its Respimat inhaler, a special atomizer for delivering liquid medication, at its Dortmund production site. The inhaler is composed of about 30 individual parts, the smallest of which weighs around 1 mg. All parts that come into contact with the agent, which includes five that are made of plastic, are manufactured by the company itself. These parts are produced under GMP and FDA-compliant conditions in GMP Grade D clean rooms.

Boehringer Ingelheim microParts' latest product expansion project revolved around the production of small and extremely small parts at its own production site in Dortmund. To do so, the company commissioned Motan-Colortronic with the design, production and installation of a new material supply system. This material supply system was to be designed for the production of small and extremely small PEEK parts with shot weights of between 0.7 and 5.5 g. In designing this system, it was important to take into account the system's low throughputs of between 200g/h and 1.2 kg/h. Further, the material drying system had to be designed such as to account for the fact that PEEK, which is a high-performance polymer, is hygroscopic and, in line with the latest processing recommendations, needs to be dried to a residual moisture content of about 0.05% at a temperature of 150 to 160 °C. Further, there was the additional requirement that the material had to stay dry while in the conical pile and right up to the point of discharge including while the machine is idle. Failure to do so would have meant that the moist material would have had to be removed and discarded under controlled conditions every time the machine was stopped. This would have been extremely expensive, as this highly special production process does not permit any of the rejects or sprue to be recycled.

As a result, the only viable option was the use of a decentralized compressed air dryer system. The dryers that were subsequently installed were modified LUXOR CA compressed air dryers manufactured by Motan-Colortronic. The dryers depressurize ultrapure compressed air from 6 bar to atmospheric pressure. This produces dry process air with a low dew point that is subsequently supplied to the drying hopper via a temperature-controlled heater, absorbs the moisture and exits the hopper via an outlet leading into a special clean room air extraction system.

In order to ensure that the compressed air dryers will work reliably even when working with low throughputs, Motan-Colortronic performed a wide range of tests and analyses at its own technical centre in Friedrichsdorf. The data from these tests were used to develop the process specifications and subsequent validation.

The average residence of the material inside the dryer is about three to four hours, with respect to which the processes are operated around the critical ranges' mean. The drying temperatures for the compressed air dryers are selected at the central operating panel. The temperature sensors are tested once a year and calibrated if necessary. The same applies for the ultrapure compressed air system in order to ensure that the compressed air is of consistent quality.

The injection moulding machines are supplied with material by Motan-Colortronic medical range CSK conveyors.

Material supply system with batch tracking

The material supply system contains two octabin stations and is located inside a separate room outside the injection moulding area. As soon as one of the bins is empty, a signal is sent to the central control unit and the two-component valve between the two octabins automatically switches from one bin to the other. However, this is only possible if the two bins contain the same batch. If this is not the case, the conveying system is disabled and a corresponding signal sent.

The process for changing the octabins is subject to a strict set of rules. Once the empty container has been removed, the machine operator has to log into the system and authenticate himself. Next, the station at which the container is to be changed has to be identified using a scanner, after which the material and batch codes of the new octabin also have to be entered into the system with the scanner. If the material code is correct, the new octabin can be fitted. Both the removal of the empty container and the fitting of a new octabin are monitored with a light barrier. The system records every deviation from these rules as an error, at which point it records the name, date and time and disables the material supply system.

Batch changes care closely linked to lot changes, which are subject to yet another strict procedure. In order to remove any pellets from the material lines when changing lots, the system has been equipped with a suction-based return line that allows the system to be completely emptied of all residues. While this process is active, the conveyor units at the injection moulding machines are disabled. Each dryer is furthermore fitted with an additional slide valve at the bottom. To ensure that the new material is completely dry, this slide valve will only open once the preset residence time has expired when the machine is restarted.

Networked control with two bus systems

Safety is critical to the manufacture of medical products. This is why is was vital to Boehringer Ingelheim microParts to employ a comprehensive system capable of enabling reliable compliance with documentation requirements and of protecting the system from incorrect and misuse.

The entire material supply system and all of the control components for the dryers and conveyors as well as the material supply scanner is consequently integrated in a centralized control unit with a LINKnet 2 visualisation system from Motan-Colortronic. This system in turn is connected to the company's Ethernet and hence the PDA system through the visualisation system. The system records and stores all data together with a time stamp, amendments, new and old values and user name.

The entire system can be operated and monitored using the LINKnet 2 visualisation system installed in the clean room or the central control unit. Each of the system's units is furthermore equipped with a decentralized operating panel that displays important data such as the unit's operating temperature and pressure.

In line with current regulations, all of the components of the material supply system are GMP/FDA compliant. The material lines and return line, including the elbows and Y-pieces, are made of borosilicate glass, and the vacuum line of V2A stainless steel. The dryers, drying hoppers and separators are made of electropolished stainless steel with specific surface roughness'. All of the above is documented in material certificates.

Tailor-made compressed air dryers for clean room production in the course of a production expansion, Boehringer Ingelheim microParts GmbH, Dortmund, set up a new clean room for the production of very small molded parts from PEEK.