62 - What needs to be considered when dosing very small amounts?

Throughput does not equal throughput – the motto of the previous issue of mo’s corner where we looked at the maximum throughput of a dosing unit, also applies when dosing very small amounts, such as when dosing colour Masterbatch. Here, ratios of just one to five percent of mass are usual. Initially, this doesn’t sound too dramatic, as these are common settings. The whole thing becomes more difficult, however, when very small shot weights are also a factor. If the product is also translucent, extremely high precision is needed.

An example to help visualise the problem:

- At a shot weight of 300 g and an additive ration of 1%, 3 g of additive needs to be dosed for each shot.

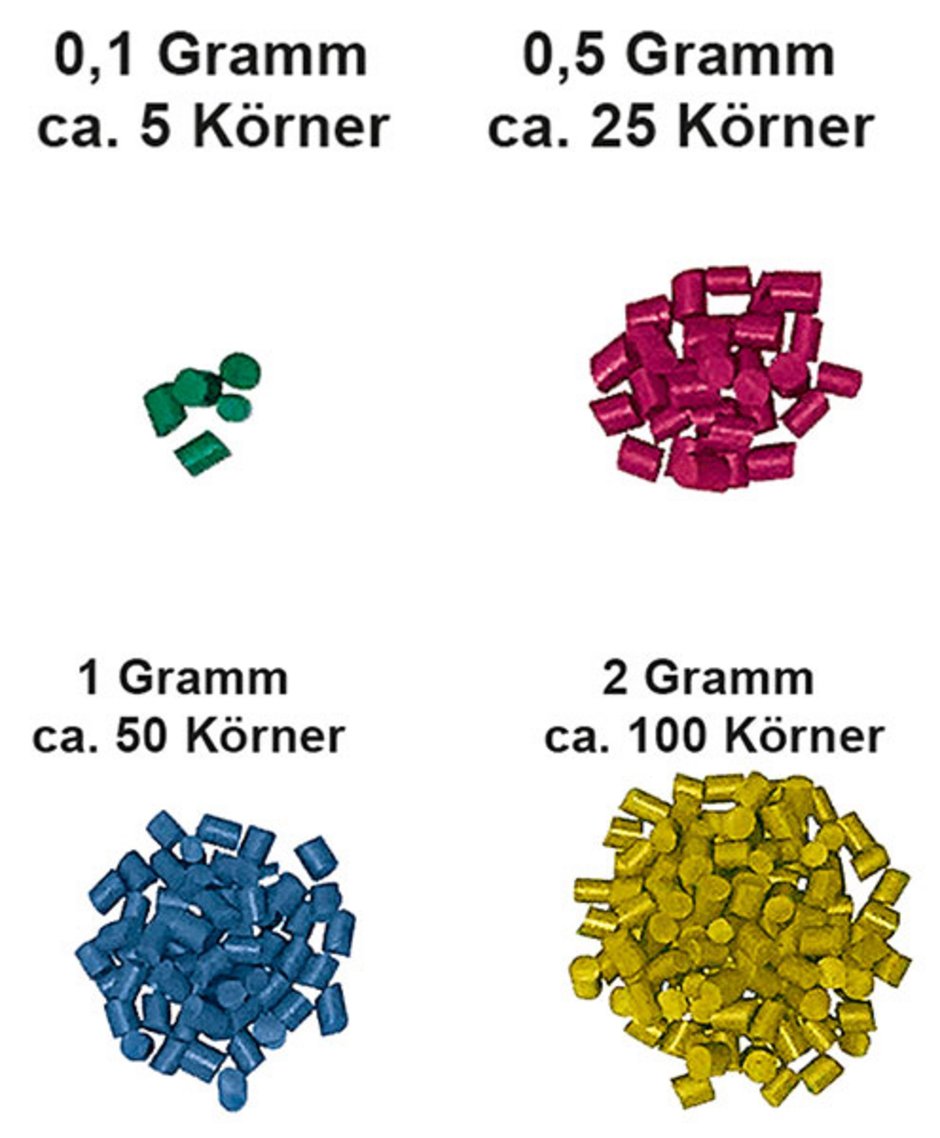

- At a shot weight of 10 g and an additive ration of 1%, 0.1 g of additive needs to be dosed for each shot.

If synchronous dosing units with free intake are being used, additives don’t only need to be added FOR every shot, but also DURING every shot. This means, for every shot according to the second example approx. 5 granules have to be dosed. The dosing device needs to be able to synchronously dose this amount precisely without fluctuations of the compound due to pulsations. Pulsations in this context means that the compound is correct over the course of multiple shots, but fluctuates slightly from shot to shot.

A quick reminder: “dosing with free intake” means that the main component is available above the free intake valve of the collection bin. All secondary components (additives) are fed from the dosing station. For injection moulding a constant material flow is taken in during the screw intake time.

Disc dosing can be a practical solution for dosing such small amounts. Disc dosing units that are equipped with a stripper can even cut individual granules to achieve optimal fill levels of the dosing chambers.

Different versions of dosing discs are available. What they all have in common are defined, separate cavities. Which disc type is most suitable depends on the required dosing rate, i.e. the amount of material to be dosed per dosing cycle / time unit. Dosing properties, i.e. bulk material properties, must also be considered.

Do you need examples of equipment with dosing discs? Visit www.motan.com for more information.