51 - How can molecular sieves be regenerated?

We already described the basic principles of regeneration in Issue 50. Depending on the design of the dryer, the regeneration (or re-drying) of the molecular sieve beds actually occurs in various different ways.

The simplest version is timed regeneration, which occurs in set intervals that determine both starting time and duration. This means the process starts and ends independently of the saturation of the molecular sieve bed. As a result, this version cannot react to changing conditions, such as material throughput or lower initial moisture levels. The energy consumption of regeneration is always that of the highest throughput and greatest initial moisture.

The more cost efficient and, in regards to energy consumption, more economic version is the combination of time and temperature controlled regeneration. The regeneration cycle is started at pre-set intervals. However, the regeneration heating phase only ends once a specific temperature has been reached at the air outlet or the bed being regenerated. Because water pulls a lot of heat out of the air when it evaporates, this temperature increase is a sign that almost no water is left bound in the molecular sieve.

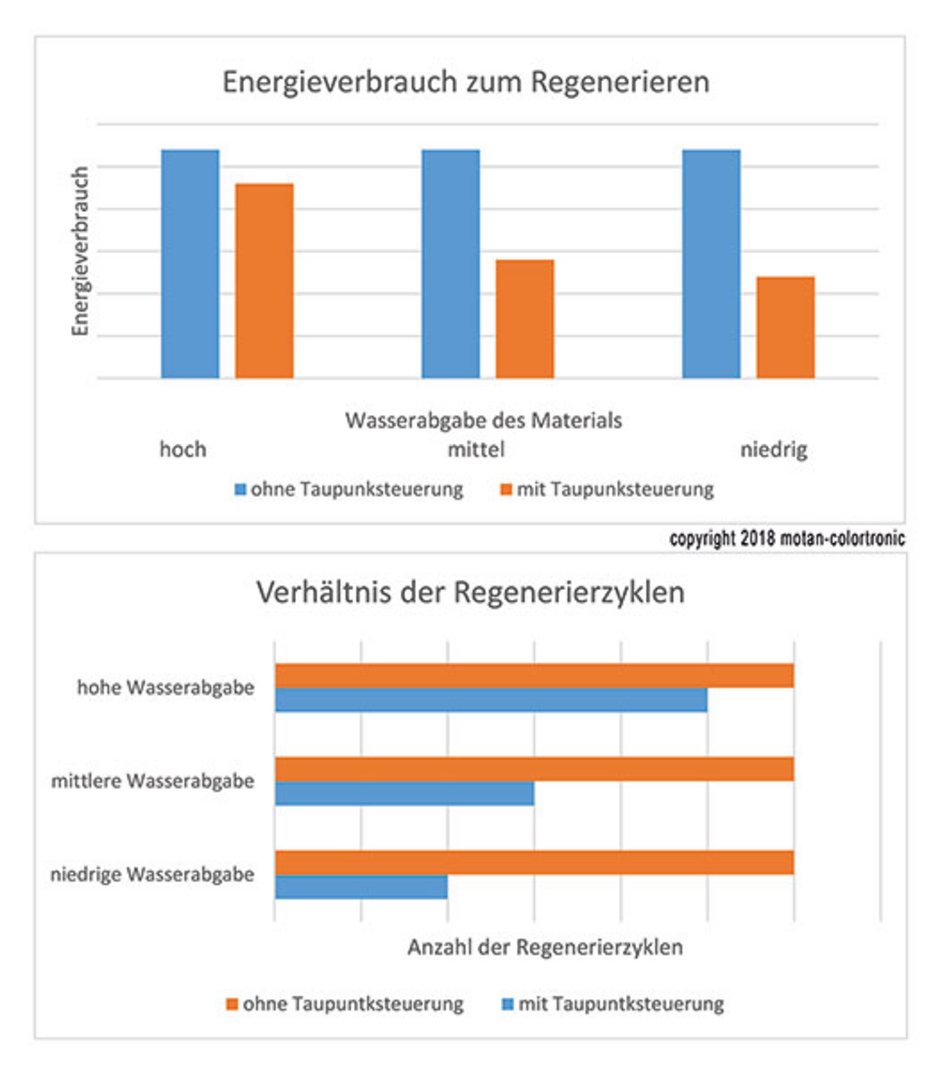

The most efficient and safest solution in dew-point controlled regeneration. Here, a sensor monitors the dew point temperature of the dry air. Regeneration is only started when the dew point temperature surpasses a pre-set target value. Combined with the previously described temperature control, this is a particularly energy efficient method of regeneration. However, it is important to calibrate the dew point sensor regularly.

Another way to save energy is the integration of a heat exchanger to feed back energy from the regeneration exhaust air. Here, the exhaust heat is fed back and not released into the environment.

In order to completely restore the adsorption capacity of the molecular sieve bed it needs to be cooled completely. This can occur in either an open or a closed cooling cycle. In an open cooling cycle the bed is cooled using environmental air and the energy is returned to the environments. A disadvantage here is that the bed can reabsorb moisture during the cooling phase. This can result in the molecular sieve reaching saturation a lot quicker when air humidity is high, such as in summer. As a result, it will need to be regenerated again much sooner. Worst case, it cannot adsorb enough moisture to reliably dry the material. This is why a closed cooling cycle without the use of humid environmental air is the better option.

You want to see a molecular sieve within a drying system? Visit www.motan.com for more!