46 - How can coupling stations be monitored?

In issue 28 we introduced different multipoint conveying systems, including machine-related conveying systems, which are connected to the different material sources via coupling stations (or tables). It is not always possible to rule out the eventuality of confusion when manually connecting the couplings, with the result that the wrong material may be conveyed to a processing machine.

This risk of failure can be reduced with the help of monitored coupling stations, where the source-destination mapping is monitored by the controls. In this case, the material is only conveyed when the source assignment, as it is saved in the controls, matches the actual destination (the hopper loader on the processing machine or the material bin). In the simplest form, it consists of wired plugs, which must be connected in addition to the couplings.

More comfortable and safer are contactless systems. One variation is a controlled slide gate, installed under the material bin. In combination with a coupling station, the conveying control monitors the source-destination mapping. If a hopper loader signals material requirement, the conveying process begins: the control starts the vacuum generator and opens the slide gate of the determined material. If the couplings are connected correctly, the material will be conveyed to the hopper loader. If the couplings are connected incorrectly, the slide gate receives the signal to open, but as the material line is not connected to the hopper loader on the machine, the material cannot be conveyed. Instead, an error message occurs.

This concept can be transferred to another variation, which operates with the help of suction valves. In this case, the corresponding suction valve is closed, so that vacuum can only be generated in the correct material line. The suction valves of the other lines remain open.

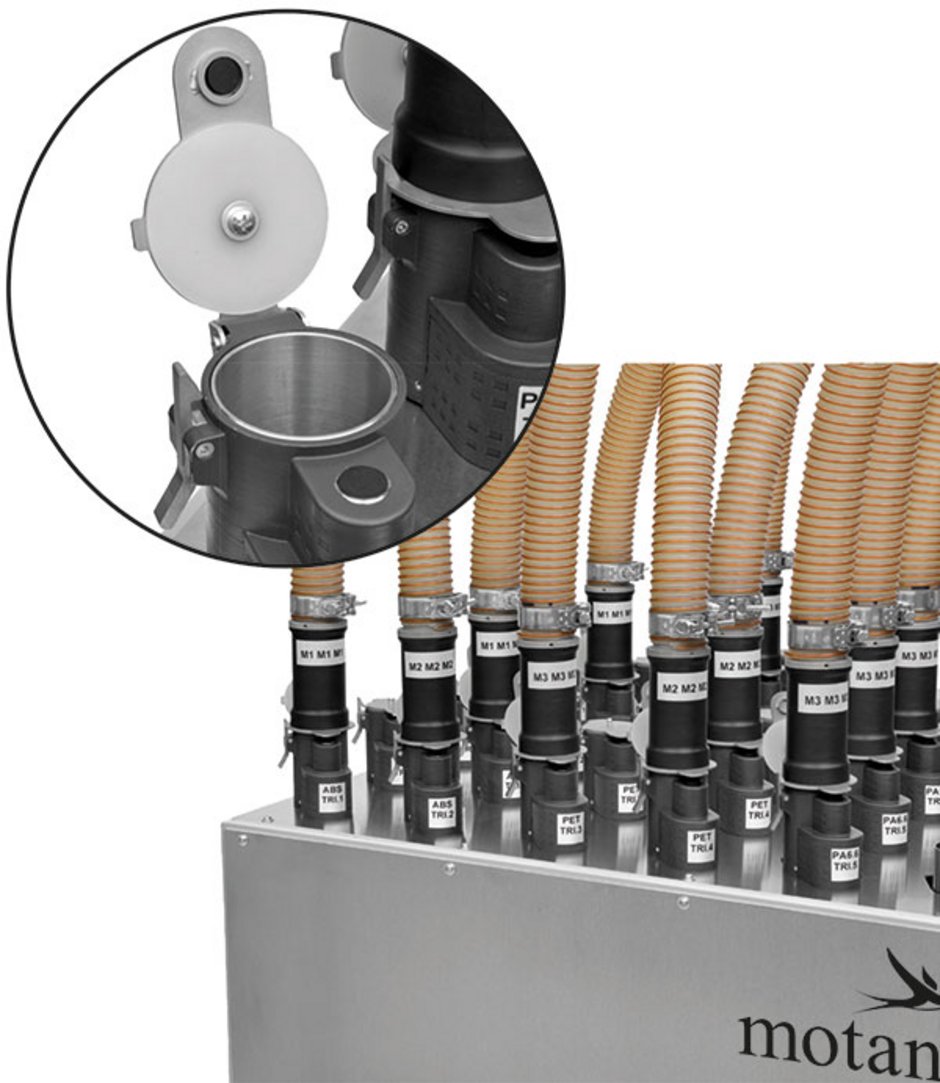

Another concept is based on RFID-technology. RFID stands for Radio Frequency Identification, a contactless identification method. RFID systems consist of a data memory (transponder) and a read-write device (sensor). The systems operate with weak electromagnetic waves, which are emitted by the sensor. When the transponder is within the receiving range of the sensor, a mutual communication between both devices starts.

For coded coupling system, the hose couplings and the lids of the coupling holders on the coupling table are each equipped with a transponder. The sensors are installed into the casing of the coupling holders

RFID-technology has many significant advantages compared to more conventional systems, such as barcodes or laser markings. An advantage is that transponder data can be read and written even without a direct line of sight to the sensor.

You want to know more about coupling stations? Find further information on www.motan.com