28 - How can multiple machines be supplied with different material?

If multiple machines in plastics processing need to supplied with different plastics, then normally the installation of a multi-point conveying systems would be sensible.

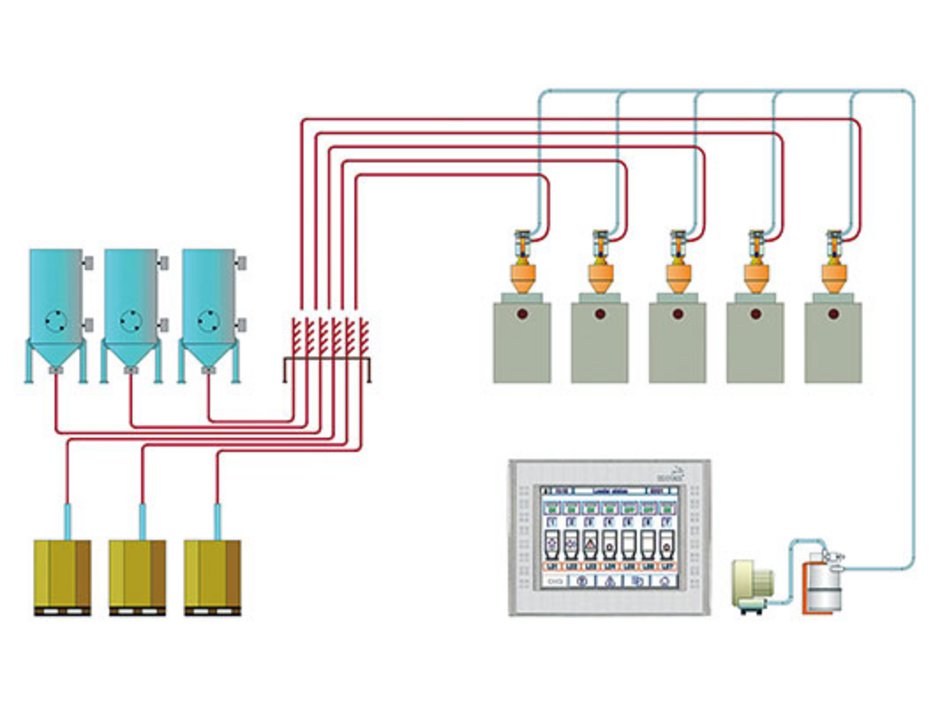

Generally, a multi-point conveying system consists of the material source (storage bin, dryer, or debagging station), the conveying lines, the vacuum lines, the material loaders, a central blower, and the controls. The material loaders signal the controls with their material demand, which starts the material conveying.

Conceptually, multi-point conveying systems are divided into material dedicated and machine dedicated systems. There are also combinations of both concepts.

The material feedlines of material related systems are dedicated to a material or correspondent storage bin. The material loaders are then fixed or connected to these lines with couplings. An advantage is the particularly distinct separation of the raw material paths, resulting in the elimination of contamination. Also, it is comparably easy to connect additional machines. A disadvantage is the reduced accessibility; for material changes, the hose between machine and material feedline line needs to be switched. If an additional material is added, a new line must be installed throughout the entire production. Material dedicated systems are mainly suited for production, where multiple machines need to be supplied by a few different materials and material changes rarely occur at the machines.

For machine dedicated conveying systems, every processing machine is assigned a conveying line. They are best suited for production with many materials, frequent material changes, and a large number of machines. The connection of the material feedlines to the different material sources occurs via coupling stations (e.g. diverters). Here, the connection to the required material source occurs manually or completely automatically. In order to avoid mix-ups, the couplings are fitted with encoders or are secured with a source-goal allocation via the software. Alternatively, shut-off valves monitored by the controls can be fitted in the material feed lines. In addition to the flexible material distribution, the low requirement of pipe installation and the central arrangement of the coupling station are advantages. In combination with dry air conveying and line purging (of the conveying line), machine dedicated systems are particularly well suited for dried material.

You need equipment for a whole conveying system? Find it on www.motan.com