22 - How does drying work?

Drying material means removing its moisture, which sounds very simplistic. The first method that comes to mind is to use the highest possible drying temperature to dry the material rapidly. This is because higher temperatures increase the air’s ability to absorb moisture. However, the nature of the material itself places limits on the drying temperature; the plastic must remain undamaged. This means the temperature must remain significantly below the material’s melting point. (Other kinds of damage are beyond the scope of this article.) Even with a drying temperature below the melting point, longer drying time carries risks – for example, over-drying.

So, how do you dry plastic granulate without damaging it? There are two key factors:

- the binding forces between the water and plastic molecules

- the vapour pressure differential between the pressure at the surface of the plastic and the partial pressure of water vapour in the air; this is also called a concentration gradient

The forces binding the water and plastic molecules, called van der Waals forces, are relatively weak, and dependent upon the strength of the polar groups in the material. As temperatures rise, the forces between the molecules grow weaker. The gecko is an example of van der Waals forces at work: their footpads are covered in fine hair-like setae. The van der Waals force of a single seta is weak, but together, the vast number of them is strong enough to allow the gecko to walk on walls and ceilings.

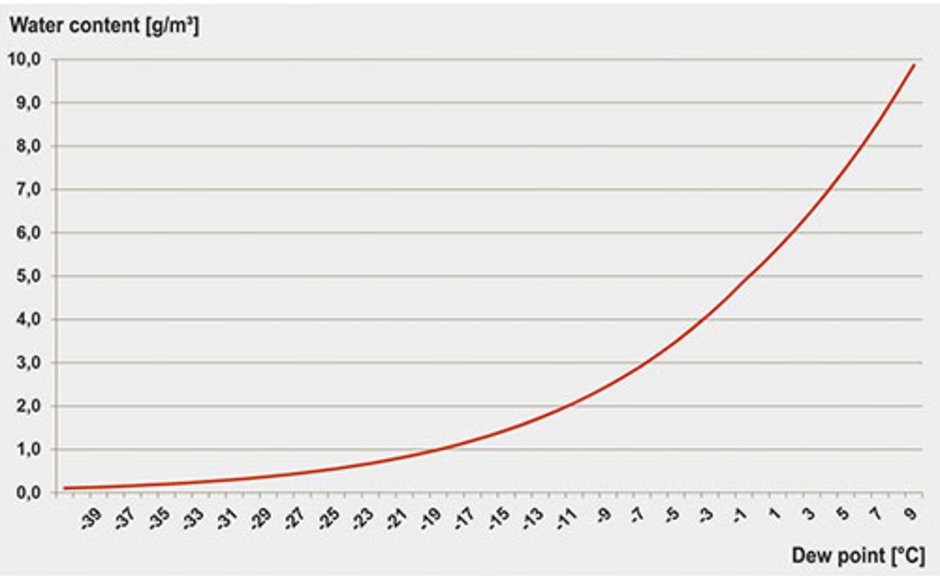

Concentration gradients play another key role. This gradient is the difference between the material’s initial moisture content and the moisture content (dew-point) of the dry air. Hygroscopic materials naturally tend towards moisture equilibrium with the ambient air. This equilibrium is dependent upon the type and temperature of the plastic, and the air parameters (relative moisture content, temperature and pressure). Heating the air, or lowering the dew-point temperature, creates a pressure differential (and a resulting concentration gradient); this causes moisture to diffuse from the plastic to the air. Higher temperatures weaken the binding forces between molecules, allowing the moisture to diffuse more easily. Additionally, hotter air can absorb greater amounts of moisture. In other words, it has a higher water affinity.

The rate at which inner moisture in the material diffuses to the surface is called the rate of diffusion. It depends on the material to be dried. It is important to note that at the beginning of the process, diffusion is more rapid due to the greater concentration gradient. As the gradient decreases, the rate of diffusion slows, until a new moisture equilibrium has been reached once more.

When drying plastic granulate, the absolute moisture content of the material is relatively low. Against this background, it becomes clear that the process air must not simply be heated to an appropriate temperature. It must also have very low moisture content, in order to develop a concentration gradient that will bring the residual moisture to the level required for further processing.

Often, in the context of drying plastic granulate, dew-points between -20 and -60°C are mentioned. In most cases, however, it is doubtful whether a very low dew-point temperature really is an advantage. Broadly speaking, process air with a low dew-point temperature does have a positive effect, at least to some extent, on the speed of plastic granulate drying. But this effect is, as previously described, limited by the maximum rate of diffusion, which in turn is dependent upon the material and temperature in question. Moreover, drying the air to achieve a very low dew-point temperature requires a significant amount of energy – and carries a risk of over-drying the material. Against this background, a dew-point temperature of approx. -20°C is sufficient for drying most hygroscopic plastics.

The experience of dryer manufacturers also plays a role. They draw on a vast number of their own tests, and information gleaned from real-world use, to offer recommendations on judicious settings.

When drying plastic material, the goal is to strike the ideal balance between drying speed and preventing damage to the material.

How can drying equipment look like? Find out here: www.motan.com