21 - How does the dew-point impact plastic granulate drying?

To recap, there are four key parameters involved in drying plastic granulate: drying temperature, air-flow, dew-point temperature and the drying time. These must be carefully balanced, as each impacts the drying process and its results.

So if one parameter is changed, the others must be altered accordingly to achieve the same outcome.

Before we examine the dew-point itself, it is important to note the following:

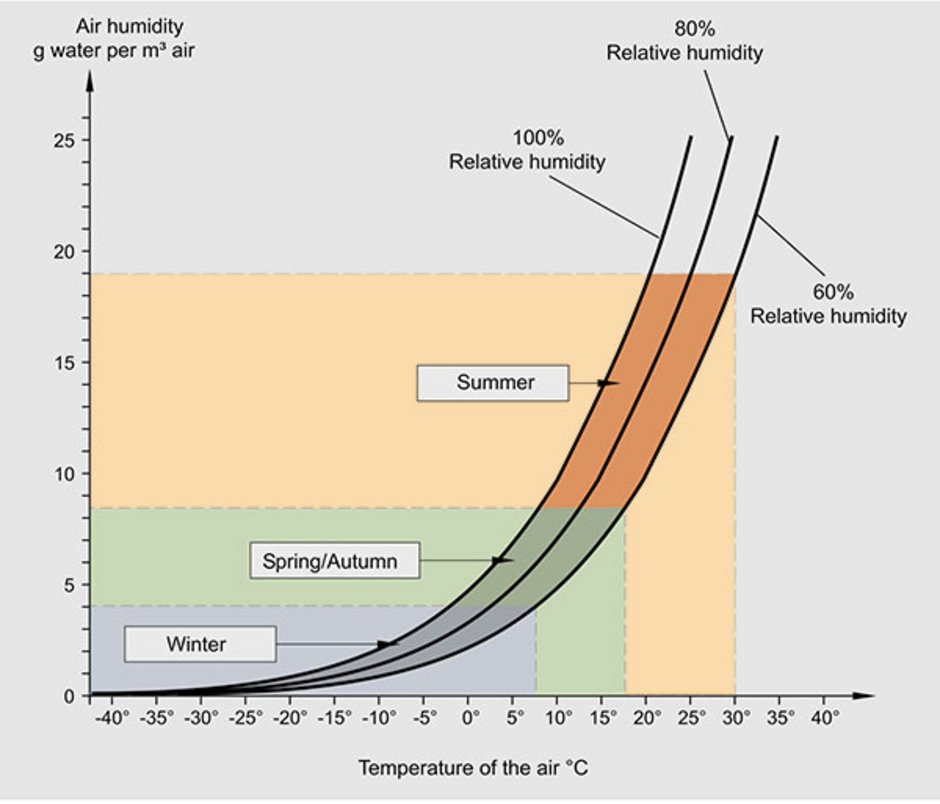

- The hotter the air, the more water (vapour) it can contain.

- As a result, maximum moisture content is dependent on air temperature.

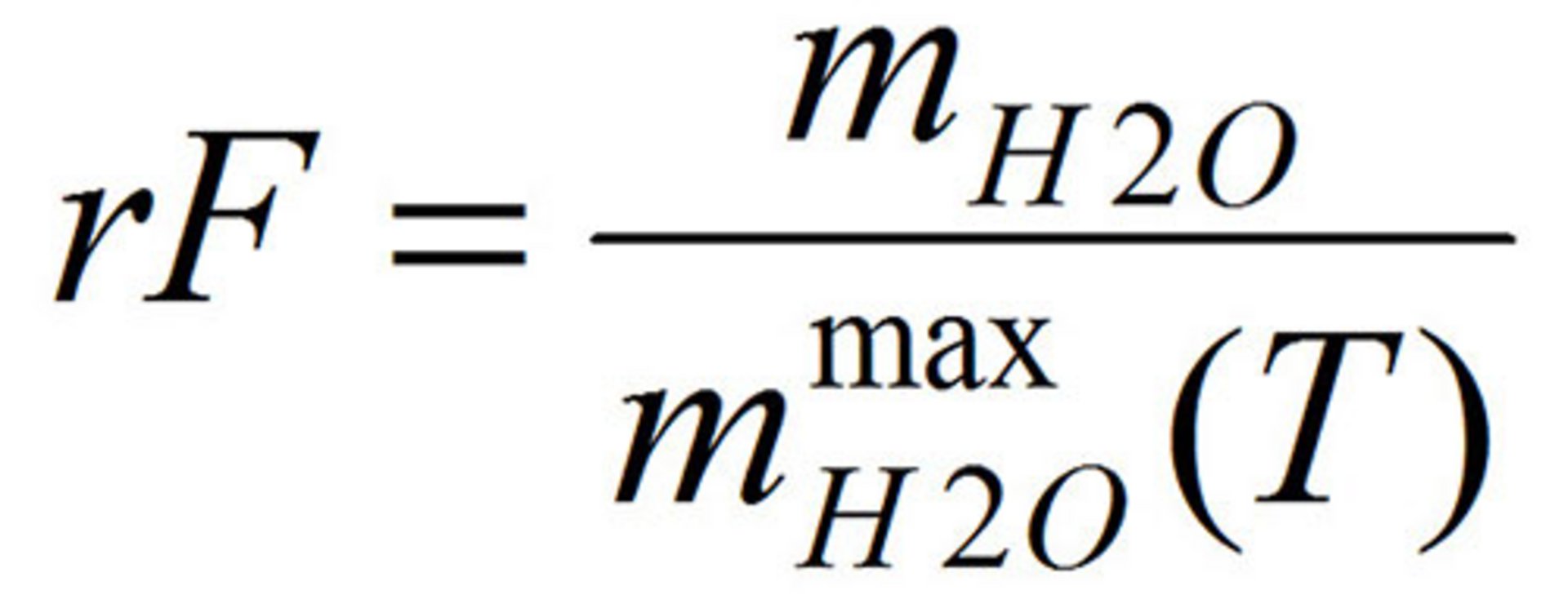

- The ratio of moisture present in the air (mH2O in g/m³), relative to the maximum possible moisture content at a given temperature (m max(T)), is called relative humidity. This ratio is expressed in percent.

When air is cooled, its maximum moisture content falls. As mmax decreases, the air’s relative humidity increases (see above formula). If the air is cooled sufficiently for relative humidity to reach 100%, the moisture condenses as droplets, forming dew, mist or rain. This occurs at a temperature called the dew-point. At 100% relative humidity, the air temperature and dew-point temperature are identical. If the post-condensation air is heated, its dew-point temperature – and therefore its absolute moisture content – remains constant, while relative humidity sinks.

The dew-point, or more accurately, the dew-point temperature, is a function of the air’s absolute moisture content (g of water vapour per m³ air), given in °C. It should be noted that the dew-point temperature is a measure of the humidity present and is not a real temperature. It is rather, temperature at which the air is 100% saturated with water vapour. It follows that for each dew-point temperature, there is a specific moisture content (see table).

In winter, people with glasses often find that their lenses fog up when they come indoors. Based on what we have learned, we now know that when this occurs, the temperature of the glasses is less than or equal to the dew-point of the ambient air. When a surface’s temperature falls below the dew-point, moisture content condenses.

In conclusion, the less moisture content in the air, the lower its dew-point. As air becomes dryer, its dew-point decreases; this is advantageous for the plastic granulate drying process. To illustrate this: when air is at 100°C, its maximum possible moisture content is 600g/m³, and at 0°C, it is only 4.8g/m³.

In hot-air drying, the dew-point is dependent on the ambient climate, while during dry-air drying with defined thresholds and in a closed environment, it remains stable regardless of ambient weather conditions. It is important to keep in mind that very low dew-point temperatures require significant energy consumption to dry the air.

A dew-point temperature of approximately -20°C is sufficient to dry the majority of hygroscopic plastics. In our experience, at static drying temperatures, variations in dew-point temperature have very little impact on drying speed. These variations, and the drying temperature, determine the lowest possible residual moisture (the equilibrium between granule moisture and dry air).

We will examine these relationships in the next edition of mo’s corner.

Any questions about drying equipment? Please find out more on www.motan.com