13 - Why should plastic granules be dried?

When manufacturing plastics, it is essential to ensure that the moisture content of the feed material is just right. In the case of injection moulding, for example, too much water in the plastic can cause all manner of problems – affecting not only the manufacturing process, but also the quality of the finished product.

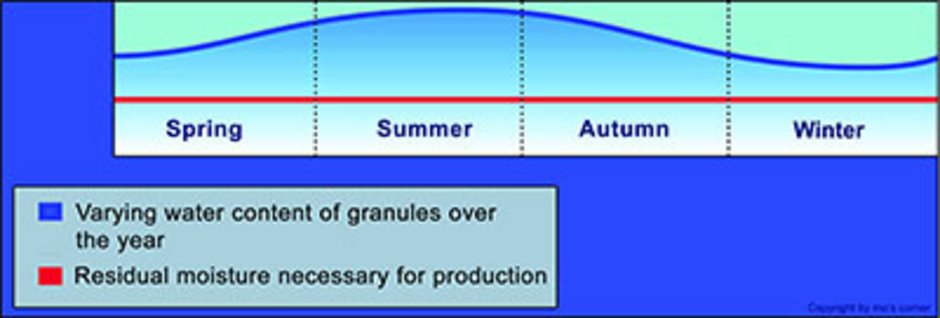

At the root of the problem lies the way plastics behave when they come into contact with moisture in the air. Many plastics are hygroscopic, meaning they absorb water right into the molecular structure of each individual granule. The resulting liquid content is sometimes referred to as ‘core moisture’.

In the case of non-hygroscopic plastics, on the other hand, moisture only collects on the surface of the material. A word of caution, however: in some instances, the fillers and reinforcing agents used in non-hygroscopic plastics can also absorb moisture.

During processing, the consequences of excess moisture range from vapour bubbles, foaming, problems filling the mould and deformation of the moulded part to inconsistent viscosity, oscillating process parameters, and fluctuations in throughput. Moreover, issues can arise further downstream for example; during painting.

In certain plastics, the presence of water during the melt phase triggers a chemical reaction called hydrolysis, which alters the molecular structure, reduces the molecular weight, and lowers viscosity as a result.

When assessing the impact of moisture on product quality, it is important to recognise that not all problems are necessarily visible. Hidden flaws such as reduced mechanical strength can only be discovered using suitable methods of analysis, mostly by means of destructive testing.

On the whole, material with excessively high moisture content can negatively impact moulded parts in practically every aspect – not only their mechanical properties, but also their optical, chemical and physical characteristics. The most obvious issues include streaks, cavities and holes, and bubbles on the surface.

However, it is also important that plastics are not over dried. They must contain a certain level of moisture if they are to be processed effectively. Each individual resin will have a specific value, calculated and stated by the manufacturer.

In conclusion, a defined and consistent residual moisture content is essential if you are to avoid waste and ensure high-quality finished products. Be careful not to overdo it, however – overly dry plastics cause problems all of their own.

Next time, mo’s corner will tackle the multifaceted issue of drying.

What different kinds of of dryers are available? More information you can find on www.motan.com