Energy-efficient technology improves productivity

Bergmann Spritzguss und Formenbau GmbH & Co. KG, which is headquartered in Telgte-Westbevern in Germany, was founded in 1989 and is an injection moulding company and system supplier that supplies a large number of customers from a wide range of industries. Bergmann offers a comprehensive range of services, ranging from the initial conception to the development and construction of plastic parts and relevant tools, as well as prototype construction, right up to the production process. The company's portfolio furthermore includes two areas of specialisation – laser radiation welding and Direct Metal Laser Sintering – that are increasingly gaining in significance.

Bergmann has two production sites. One in Telgte and, since 2000, one in Czaplinek (Poland). It currently owns 75 injection moulding machines with clamping forces of between 250 to 10,000 kN, which include two 2-component machines, all of which are equipped with parts removal devices. The company currently employs around 290 people, 72 of which work in Telgte, twelve of which are apprentices. Each of the company's production sites has a production area of around 10,000 m² and are predominantly used to produce technical parts as well as assembled components over three shifts a day. The parts it produces range from extremely small precision parts with a part weight of 0.5 grams to large products weighing 5.8 kg. The company processes around 4000 tons of plastic annually, all of which are thermoplastics (with the exception of PVC). This means that Bergmann processes a wide range of different materials, which include 50 different types of material alone that require drying. On average, tools have to be changed five times a day. The company has 20 toolroom staff who design and manufacture between 80 and 100 injection moulding tools with dead weights of up to eight tons for the company's own production every year.

Production expansion with central material supply system

As the production facility in Telgte reached a stage where it could no longer cope with the increase in demand, Herbert Bergmann, founder and managing director of the company, decided to invest and extensively expand the facility. The company subsequently built two new halls – one for production and another for a central material supply system and material storage – with the aim of optimising material flow.

Up until then, the material supply system had been located inside the production hall, which had resulted in corresponding disadvantages because it took up much needed space, created a lot of noise and heat, as well as granulate residues on the floor. The aim had subsequently been to keep the two systems completely separate and keep the production area free from any stand-alone units, sacks and containers with granulate and colouring agents. In order to do make this a possibility, all of the machines were going to be equipped with new conveyors and their own colour dosing systems, as well as adapters to make it possible to use the systems interchangeably should the need arise. At this stage, the materials handling operations had also required full-time attendance by three remembers of staff that were urgently needed at another place.

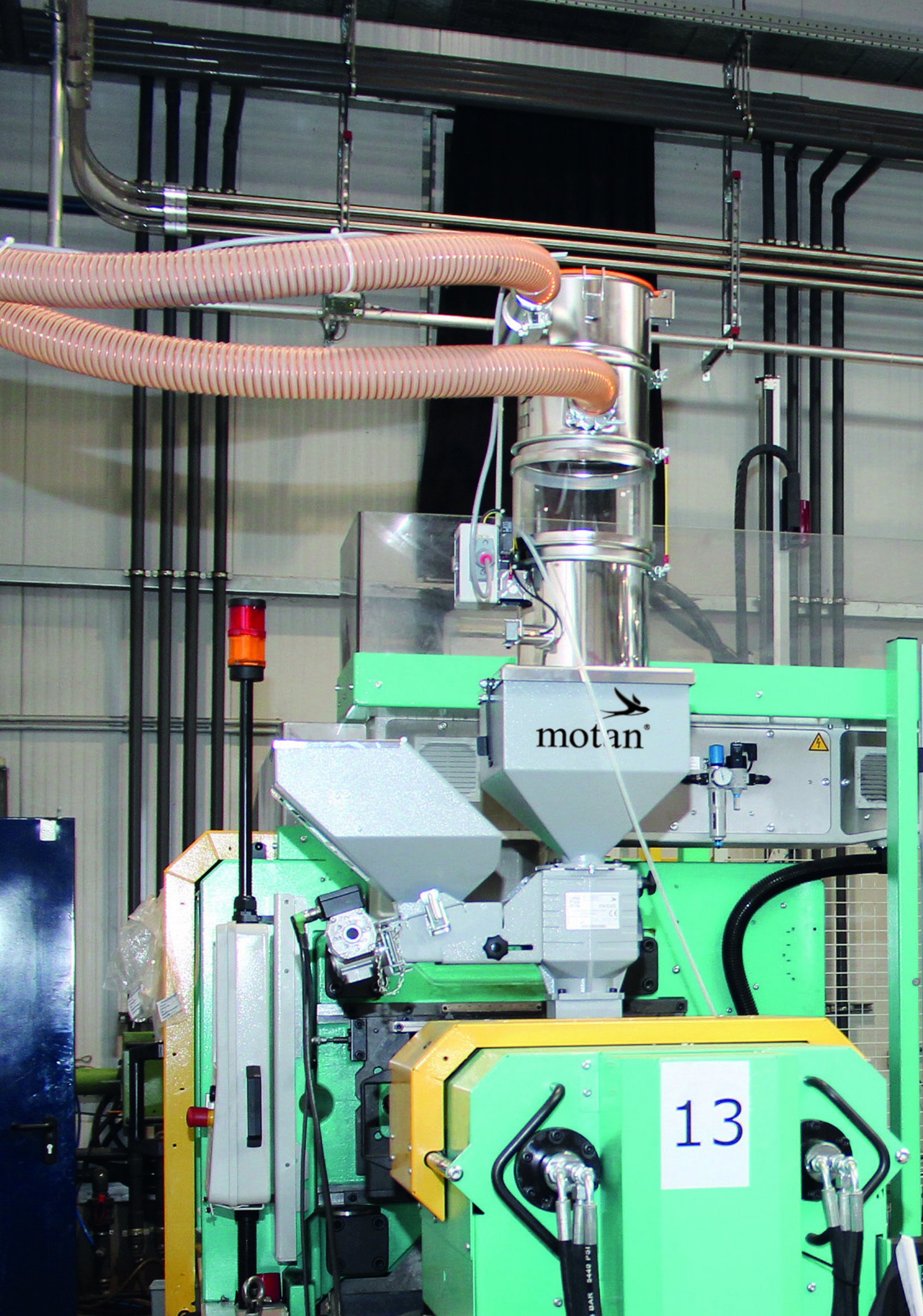

Bergmann commissioned the Northern KFW office of Kunststofftechnik Flink & Wortmann GbR (KFW) – a Motan-Colortronic distribution partner – to design and build the new system. The entire design and construction process, from the first contact from Bergmann to the date the system was commissioned, took no more than six months.

When it came to designing the system, there were two key considerations that had to be taken into account: One of these was that the machines had to be directly supplied with material and the other was that it had to be ensured that there would always be dried material available. This required finding a balanced and economical solution regarding the size of and number of drying hoppers. Initially, there were16 injection moulding machines that needed to be supplied with material. However, as part of this ongoing expansion, another four machines were added to the project as planning was still under way.

On completion, the project comprised the design and construction of a material supply system with ten Luxorbin drying hoppers, six of which with a volumetric capacity of 400 litres each, and two each with volumetric capacities of 250 and 150 litres each. Within this system, the dry air is supplied by a Luxor 1200 dry air generator with DryingOrganizer to protect material from being over-dried and hygroscopic polymers from being insufficiently dried. The dry air generator's control unit can control and monitor up to 16 drying hoppers, associated conveyors and discharge valves, as well as 24 materials handling units. Every drying hopper is assigned a storage tank.

The concept is based on a machine-specific conveyor system, which means that every processing machine has its own material supply line. This principle is particularly suited for production processes that involve a high number of materials, frequent material changes and a large number of machines. Machine-specific systems are very suitable for supplying dried materials when used with a dry air supply system and discharge valves for the supply lines. When long distances are involved, dry air supply systems with discharge valves have the advantage of preventing the material in the supply lines from being re-moisturised.

The drying hoppers and several separate service tanks are connected to the material lines leading to the machines through a coupling station through which several machines can be supplied at the same time. The coupling station is equipped with suction lances that can be connected to an additional back-up dryer or a service tank when required when processing small quantities of materials. One of the drying hoppers and two supply lines are reserved for transparent and white material. This drying hopper is furthermore fitted with a HEPA filter between the heater and hopper.

The coupling station is operated, i.e. the lines are connected and disconnected, by personnel. For safety, the system also features a material path selection system (target-source assignments), where personnel have to enter the address of the source (drying hopper) and target (machine) at the control. Provided the lines have been correctly connected, the material will subsequently flow accordingly. If one of the two addresses is incorrect, the material will not flow, because only the material slide gate of the correct drying hopper will be opened. This principle ensures that materials are not mixed up.

Starting from the coupling station, a near 1000 metres of pipes were laid throughout the rest of the production hall. The pipes leading to the machines are made of wear-resistant stainless steel, while the pipe bends are made of borosilicate glass. The flexible connections between the material lines and machines were realised using high-quality PUR ductings.

Higher productivity – higher energy efficiency

The vacuum is generated by two frequency-controlled blowers inside the system that are coupled to one another. One of these supplies the drying system and the other is for the material supply to the machines. In order to safeguard production, both of the blowers' performance has been selected such that each one of them could take over all of the supply processes in the system in the event the other fails or has to be serviced. In that case, the switch will happen automatically.

To make sure that the material is transported in a careful way, the blowers can be operated at variable speeds, which is a way to affect the speed at which the material is transported. This means that every machine and its conveyor – as well as every material – can be assigned an optimum conveying speed. This solution is designed both to protect the system components from wear and to protect the material itself.

Thanks to the throughput-dependent drying process and associated use of frequency-controlled pumps, the production system has become significantly more energy efficient. Even though actual electricity consumption has not yet been determined in detail, initial rough estimates indicate significant energy savings. The automated material supply system furthermore means that production processes are more reliable and that less material is being used.

The system's operation is supported by a database stored in the dryer control that contains the drying parameters for more than 70 standard materials. This means that the only action required by personnel is to select the correct material. The corresponding information is furthermore also displayed on a terminal in the production hall. If necessary, the system can also be protected by setting up password protection for different operating levels.

www.spritzguss-bergmann.de

www.motan-colortronic.com

www.flinkundwortmann.de

Contact:

motan-colortronic gmbh

Rüdiger Kissinger

Otto-Hahn-Str. 14

61381 Friedrichsdorf / Germany

Tel. +49 6175 792-214

ruediger.kissinger@motan-colortronic.de

www.motan-colortronic.com

The company subsequently built two new halls – one for production and another for a central material supply system and material storage – with the aim of optimising material flow.